The Art of Selecting and Applying Aluminum Sheet

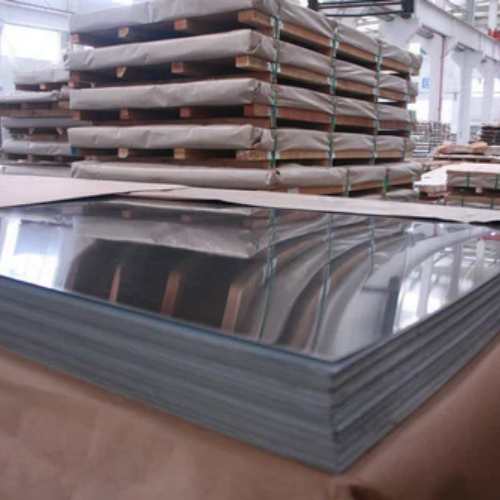

Aluminum sheet is essential in a wide range of industries, from aerospace and automotive to construction and marine, and is highly regarded for its superior lightness, strength, and corrosion resistance. However, the key to maximizing its potential lies in understanding the nuances of selecting aluminum sheet. When considering aluminum sheet, it is important to consider a few key factors to guide your decision: thickness, alloy type, and the specific requirements of the application.

Alloys such as 5052 aluminum sheet, 6061 aluminum sheet, and 7075 aluminum sheet each have unique properties, presenting a variety of strengths and resistance to environmental wear and tear. For example, 5052 aluminum sheet is known for its superior performance in harsh marine environments, while 6061 aluminum sheet is a top choice for structural components, highly regarded for its versatility and durability. On the other hand, 7075 aluminum sheet is known for its excellent strength-to-weight ratio, and shines in aerospace and high-stress applications.

Processing by aluminum sheet manufacturers further enhances its adaptability. Whether through cutting, milling, or welding, these techniques can shape the material to meet the exacting specifications required by engineers and designers.

This convergence of properties – lightness, resilience and processing flexibility – makes aluminum sheet the cornerstone for creating durable, cost-effective solutions that drive performance across industries and deliver lasting results where it matters most.

Lingchuang Steel Group Co., Ltd.

Lingchuang Steel Group Co., Ltd.