Colored Aluminum Foil

- LocationChina

- StandardAISI, ASTM, DIN, JIS, GB, JIS, SUS, EN

- Delivery Time7-15 Days

Colored aluminum foil is a versatile, high-quality material used in packaging, decoration, and craft projects. Available in a range of vibrant colors, it combines the durability and lightweight properties of aluminum with aesthetic appeal. Ideal for both industrial and consumer applications, it provides excellent resistance to moisture, heat, and corrosion.

Colored aluminum foil is a versatile, high-quality material used in packaging, decoration, and craft projects. Available in a range of vibrant colors, it combines the durability and lightweight properties of aluminum with aesthetic appeal. Ideal for both industrial and consumer applications, it provides excellent resistance to moisture, heat, and corrosion.

Pecifications

| Item | Supplier Catering Aluminium Foil, Silver Aluminium Foil Paper, Food Packing Household Aluminium Foil |

| Type | heavy gaugefoil, medium gauge foil, light gauge foil |

| Alloy Type | 1100, 1145, 1050, 1060, 1235, 3003, 5052, 5A02, 8006, 8011, 8079 |

| Thickness&Tolerance | 0.006~0.02mm (Tolerance=±6%) |

| Width&Tolerance | 280mm-1500mm (Tolerance: 1mm) |

| Temper | O, H16, H18, H20, H22, H24, H26, etc. |

| Typical Core I.D. | 76mm,152mm |

| Inner Core Materials | Aluminum core |

| Mechanical Properties | Tensile Strength (U.T.S): 35 MPA – 100 MPA |

| Elongation≥0.5% | |

| Standard | ASTMB209, EN573-1S |

| Packaging | Seaworthy Export Standard Wooden Box |

| Application | Cigarette Packaging, Lamination and Food Packaging |

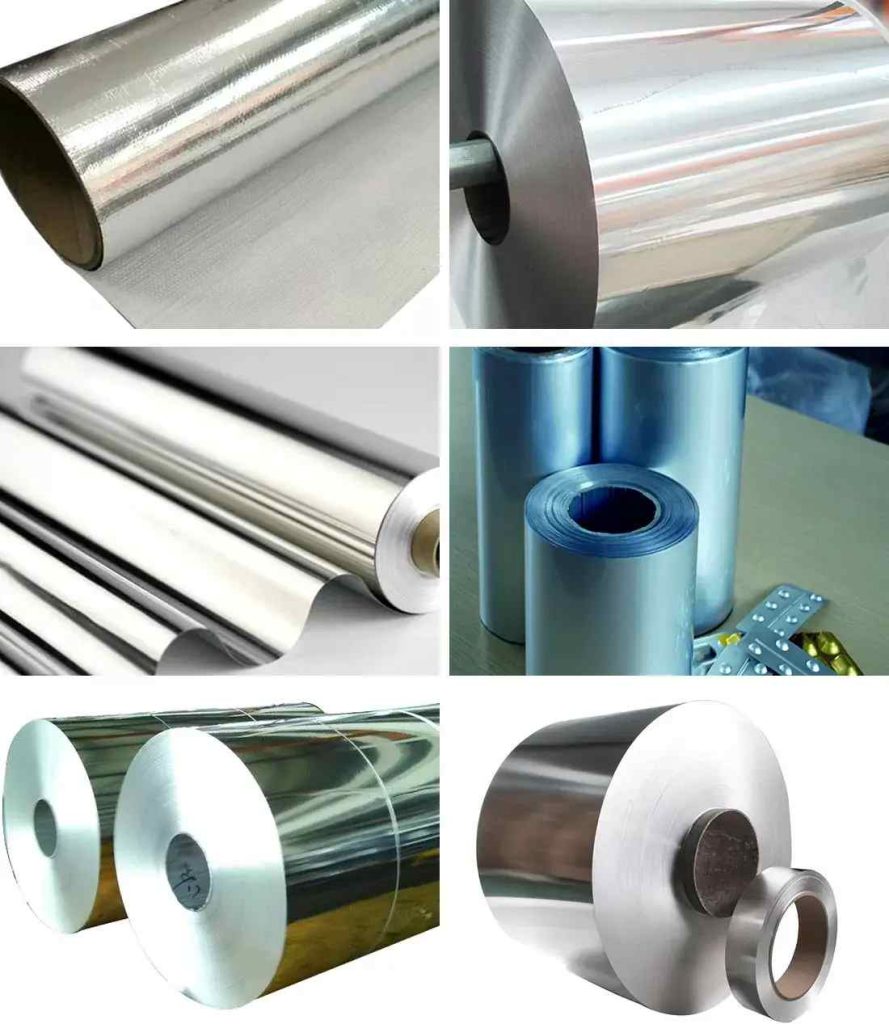

Shape

Aluminum foil can be divided into roll aluminum foil and sheet aluminum foil according to its shape. Aluminum foil deep processing wool is mostly supplied in roll form, and sheet aluminum foil is only used in a few handicraft packaging situations.

Aluminum foil can be divided into hard foil, semi-hard foil and soft foil according to the state.

① Hard foil: Aluminum foil that has not been softened (annealed) after rolling, and has no residue on the surface without degreasing. Therefore, rigid foil must be degreased before printing, lamination, and coating. If it is used for forming processing, it can be used directly.

② Semi-hard foil: Aluminum foil whose hardness (or strength) is between hard foil and soft foil, usually used for forming processing.

③Soft foil: Aluminum foil that has been fully annealed and softened after rolling. The material is soft and there is no residual oil on the surface. Most application areas such as packaging, lamination, electrical materials, etc. use flexible foils.

surface condition

Aluminum foil can be divided into one-sided smooth aluminum foil and two-sided smooth aluminum foil according to the surface condition.

①Single-sided aluminum foil: Double-rolled aluminum foil. After being rolled, one side is bright and the other side is dark. Such aluminum foil is called one-sided smooth aluminum foil. The thickness of one side of plain aluminum foil usually does not exceed 0.025mm.

②Double-sided aluminum foil: A single rolled aluminum foil, with both sides in contact with the rollers. The two sides of the aluminum foil are divided into mirror double-sided aluminum foil and ordinary double-sided aluminum foil due to the different surface roughness of the rollers. The thickness of double-sided aluminum foil is generally not less than 0.01mm.

Processing status

Aluminum foil can be divided into plain foil, embossed foil, composite foil, coated foil, colored aluminum foil and printed aluminum foil according to the processing state.

① Plain foil: Aluminum foil that has not undergone any other processing after rolling, also called light foil.

②Embossed foil: Aluminum foil with various patterns embossed on the surface.

③ Composite foil: Composite aluminum foil formed by laminating aluminum foil with paper, plastic film, and cardboard.

④Coated foil: Aluminum foil coated with various resins or paints on the surface.

⑤Colored aluminum foil: Aluminum foil coated with a single color on the surface. ⑥Printed aluminum foil: Aluminum foil that forms various patterns, patterns, text or pictures on the surface by printing. It can be one color, up to 12 colors.

Soft aluminum foil can also be further pressed into 40% foil for high-end decoration.

Features

Aluminum foil has a clean, hygienic and shiny appearance. It can be made into integrated packaging materials with many other packaging materials, and the surface printing effect of aluminum foil is better than other materials. In addition, aluminum foil has the following characteristics:

(1) The surface of aluminum foil is extremely clean and hygienic, and no bacteria or microorganisms can grow on its surface.

(2) Aluminum foil is a non-toxic packaging material that can be in direct contact with food without any danger to human health.

(3) Aluminum foil is a tasteless and odorless packaging material that will not cause any odor to the packaged food.

(4) If the aluminum foil itself is not volatile, it and the packaged food will never dry or shrink.

(5) No matter whether it is at high temperature or low temperature, there will be no grease penetration in the aluminum foil.

(6) Aluminum foil is an opaque packaging material, so it is a good packaging material for products exposed to sunlight, such as margarine.

(7) Aluminum foil has good plasticity, so it can be used to package products of various shapes. Containers of various shapes can also be made at will.

(8) Aluminum foil has high hardness and high tensile strength, but its tear strength is low, so it is easy to tear.

(9) Aluminum foil itself cannot be heat-sealed. It must be coated with a heatable material, such as PE, on its surface to achieve heat sealing.

(10) Adverse reactions may occur when aluminum foil comes into contact with other heavy metals or heavy metals.

MESSAGE:

Lingchuang Steel Group Co., Ltd.

Lingchuang Steel Group Co., Ltd.