Extending the Service Life of Galvanized Coils: Essential Factory Processes

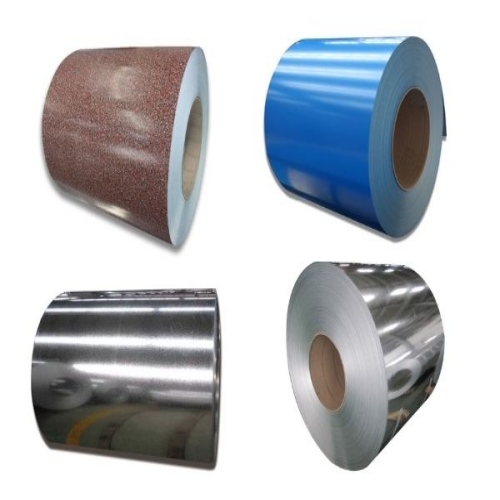

To enhance the service life of galvanized coils, factories must prioritize galvanized coil corrosion protection techniques. This includes applying advanced coatings and treatments to ensure that the zinc layer remains intact, preventing rust and deterioration. A well-maintained protective coating ensures that the galvanized surface can withstand exposure to harsh weather and industrial environments, significantly improving durability.

Another critical factor in extending the lifespan of galvanized coils is optimizing the galvanized coil manufacturing process. Using high-quality raw materials and precise control during the galvanizing process can result in stronger, more resilient coils. Additionally, advanced production technology can improve uniformity and the quality of the zinc coating, ensuring enhanced protection.

Finally, regular galvanized coil maintenance is vital to prolonging its service life. Factories need to implement regular inspections, cleaning, and re-coating to maintain the performance of galvanized coils. Consistent maintenance routines will reduce wear and tear, preventing costly replacements and ensuring long-term operational efficiency.

Lingchuang Steel Group Co., Ltd.

Lingchuang Steel Group Co., Ltd.